Comprehensive Guide to Material Selection in Renovation

Considering Durability and Maintenance Requirements

Material Selection for Long-Term Durability

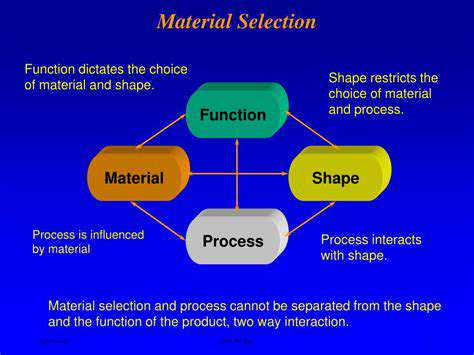

Selecting the optimal material for any project demands careful attention to its ability to withstand the test of time. Environmental conditions, stress levels, and maintenance frequency all weigh heavily in this critical decision. What might appear as a budget-friendly choice upfront could spiral into repeated repair expenses later. Professionals must examine corrosion resistance, weathering capabilities, and abrasion tolerance thoroughly. Mechanical properties like tensile strength and elasticity can't be overlooked either - they determine how well the material handles expected loads.

Time-induced degradation warrants special focus. Sun exposure, temperature swings, and chemical interactions all contribute to material breakdown. Opting for inherently resistant materials minimizes future headaches and replacement costs.

Maintenance Schedules and Protocols

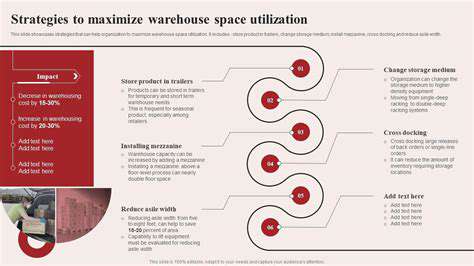

Consistent upkeep forms the backbone of material preservation. Customized maintenance plans, designed around specific material needs and environmental factors, can dramatically prolong service life. These plans should incorporate regular damage inspections, wear assessments, and appropriate cleaning methods. Meticulous record-keeping helps spot patterns and emerging issues before they escalate.

Clear repair protocols make all the difference when problems arise. Detailed manuals ensure maintenance teams follow standardized procedures for interventions, keeping operations smooth and efficient.

Impact of Environmental Factors

Mother Nature plays a decisive role in material performance. Harsh conditions like temperature extremes, moisture exposure, or corrosive elements can rapidly accelerate wear. Materials destined for marine environments demand far greater corrosion resistance than their indoor counterparts. Smart selection means matching material properties to anticipated environmental challenges.

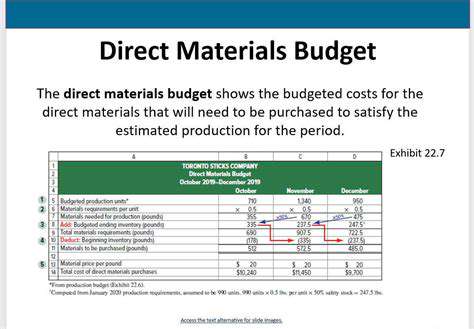

Cost-Benefit Analysis of Materials

While upfront costs grab attention, savvy planners look at the complete financial picture. That bargain material might need constant attention or early replacement, negating any initial savings. Comprehensive cost analysis should factor in purchase price plus projected maintenance and replacement expenses over the product's entire lifespan.

Assessing Material Compatibility

Material interactions can make or break a project's longevity. Some combinations trigger accelerated deterioration - think galvanic corrosion between dissimilar metals. Consulting compatibility charts or material experts prevents expensive mistakes and ensures structural harmony.

Material Testing and Standards

Rigorous testing separates reliable materials from potential failures. Laboratory evaluations provide crucial data on stress resistance and environmental performance. Industry standards offer quality benchmarks, giving confidence that materials will perform as expected under real-world conditions.

Sustainability and Environmental Impact

Material Selection and Environmental Footprint

Environmentally conscious material choices consider impacts across the entire product lifecycle. Sustainable materials reduce ecological harm from extraction through disposal. Key metrics include embodied energy, water usage, and carbon emissions. Renewable resources typically outperform finite materials in environmental impact assessments. Transparent supply chains ensure ethical sourcing practices.

Recycling and Waste Management

Effective recycling systems transform waste into resources, supporting circular economies. Design for recyclability and incorporating recycled content minimizes waste streams. Manufacturing efficiency and disassembly-friendly designs further reduce environmental burdens. Robust recycling infrastructure and consumer education dramatically cut landfill contributions.

Life Cycle Assessment and Material Alternatives

Life cycle assessment (LCA) tools reveal a material's true environmental cost from cradle to grave. These comprehensive evaluations help identify improvement opportunities. Emerging alternatives like bio-based materials or low-impact composites offer promising sustainable solutions. Ongoing material science innovations continuously expand eco-friendly options. Creative reuse strategies and closed-loop systems push sustainability boundaries further.

The path to sustainable material use requires collaboration across industries. Regular strategy updates ensure alignment with evolving environmental standards and technological breakthroughs. Through persistent innovation and shared knowledge, we can build a greener material future.