Expert Advice on Full Package Material Sourcing for Renovations

Identifying Your Needs

Before you even begin to search for material suppliers, it's crucial to clearly define your specific needs. What materials do you require? What are the exact specifications, including dimensions, tolerances, and desired properties? Understanding your needs is the first step in finding the right supplier and avoiding unnecessary delays or complications. Thoroughly documenting these requirements ensures you can effectively compare different suppliers and select the best fit for your project.

Consider factors such as the quantity needed, the delivery schedule, and any potential customizations. Having a detailed understanding of your requirements will allow you to efficiently filter suppliers and focus your search on those who can meet your specific needs. This proactive approach will save you time and resources in the long run.

Exploring Different Supplier Types

The world of material suppliers is diverse, ranging from large, multinational corporations to smaller, specialized businesses. Understanding the different types of suppliers available can help you make informed decisions. Large corporations often offer a wide range of materials and extensive logistical capabilities, but their processes might be less flexible. Smaller, specialized suppliers may focus on niche materials or unique processing techniques, providing more customized solutions but potentially with limited quantities or slower delivery times.

Consider the size and scope of your project when choosing between these options. For large-scale projects, a large corporation might be the ideal choice, while smaller projects could benefit from the personalized service of a specialized supplier.

Evaluating Supplier Capabilities

Once you've identified potential suppliers, it's essential to evaluate their capabilities. This involves scrutinizing their technical expertise, their production capacity, and their quality control processes. Look for evidence of certifications and industry recognition, such as ISO certifications, which demonstrate a commitment to quality and standards. Checking their past projects and client testimonials can give you valuable insights into their reliability and ability to meet deadlines.

Assessing Pricing and Payment Terms

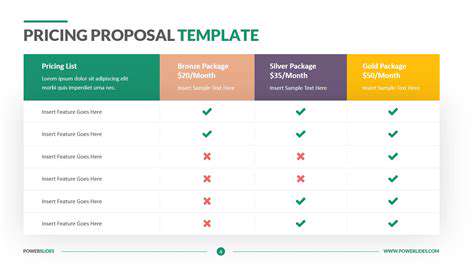

Pricing is a critical factor in selecting a material supplier. Don't just focus on the initial cost; consider the overall cost of ownership, including potential hidden fees, delivery charges, and any additional services. Thoroughly compare pricing structures and payment terms from different suppliers to get a holistic view of the financial commitment involved. Inquire about discounts for bulk orders or long-term contracts, as these can significantly impact the overall cost of your project.

Understanding Delivery and Logistics

Reliable and timely delivery is paramount in material supply chains. Inquire about the supplier's delivery capabilities, including their geographic reach, transit times, and handling procedures. Consider factors such as warehousing facilities, inventory management systems, and their ability to handle potential logistical challenges. Understanding these aspects will help minimize potential delays and ensure the timely completion of your project.

Building Relationships and Networking

Building strong relationships with your material suppliers is key for long-term success. Attend industry events, participate in online forums, and proactively communicate with potential suppliers. Establishing rapport with your chosen supplier can lead to better negotiation outcomes, potential expedited service, and access to exclusive deals. Building these connections allows for a more collaborative approach to sourcing materials.

Managing Risk and Maintaining Quality Control

Throughout the entire process, it's crucial to manage potential risks and maintain quality control. Establish clear communication channels with your suppliers, ensuring that expectations are clearly defined. Implement a robust quality control process to monitor the materials received, ensuring they meet your specifications. This proactive approach helps mitigate risks associated with defects or inconsistencies in materials. Proactively addressing potential issues will prevent costly delays and ensure the project's success.

Optimizing Your Sourcing Strategy: Cost-Effective Procurement

Understanding Your Needs

A critical first step in optimizing your sourcing strategy is a thorough understanding of your organization's specific needs. This involves analyzing your current procurement processes, identifying key materials or services required for operations, and determining the volume and frequency of those needs. This detailed analysis should also consider future growth projections and potential shifts in demand, ensuring your sourcing strategy is adaptable and forward-thinking, not just reactive to current requirements.

Exploring Different Sourcing Options

Once your needs are well-defined, it's time to explore diverse sourcing options. This includes evaluating various suppliers, considering their capabilities, track records, and pricing models. Don't limit yourself to traditional suppliers; consider alternative providers, emerging technologies, and innovative solutions that might offer unique advantages, such as reduced lead times or improved quality. Expanding your supplier base can enhance your negotiating power and resilience.

Developing a Robust Supplier Relationship Management System

Effective supplier relationship management (SRM) is essential for long-term cost savings and supply chain stability. A robust SRM system should include clear communication channels, performance metrics, and consistent evaluation processes. Establishing strong relationships with key suppliers fosters trust and collaborative problem-solving, leading to mutually beneficial outcomes and potentially lower costs in the long run.

Leveraging Technology for Efficiency

Technology plays a crucial role in optimizing sourcing strategies. Implementing procurement software and utilizing data analytics tools can streamline processes, automate tasks, and provide valuable insights into supplier performance. By leveraging technology, your team can spend less time on manual tasks and more time on strategic sourcing decisions, ultimately leading to more efficient and cost-effective procurement.

Negotiating Favorable Contracts

Negotiating favorable contracts is a key component of cost-effective procurement. Thorough research on market pricing, competitive analysis, and understanding your organization's negotiating power are crucial. A well-prepared negotiation strategy, coupled with a clear understanding of your needs and the supplier's capabilities, can lead to significant cost reductions without compromising quality or essential service levels.

Monitoring and Evaluating Results

A crucial aspect of optimizing your sourcing strategy is establishing a system for monitoring and evaluating results. Tracking key metrics such as procurement costs, supplier performance, and delivery times allows you to identify areas for improvement. Regular reviews and adjustments to your sourcing strategy based on data-driven insights ensure continuous optimization and maintain cost effectiveness over time. This ongoing evaluation is essential for adapting to changing market conditions and maintaining a competitive edge.

Ensuring Quality and Compliance: A Critical Aspect of Sourcing

Ensuring a Robust Quality Control System

A robust quality control system is crucial for maintaining high standards and ensuring customer satisfaction. Implementing clear procedures and protocols across all stages of production, from raw material sourcing to final product delivery, is essential. This approach not only guarantees product quality but also mitigates potential risks and ensures consistent outcomes.

Thorough testing and evaluation at each stage of production are vital components of a robust quality control system. This proactive approach allows for the early identification and rectification of any issues, preventing them from escalating and impacting the final product. Regular audits and performance reviews are also critical to identifying areas for improvement and maintaining the system's effectiveness over time.

Adhering to Industry Standards and Regulations

Staying abreast of and adhering to industry standards and regulations is paramount for maintaining quality and compliance. This includes understanding and complying with relevant safety standards, environmental regulations, and industry best practices. Failure to do so can lead to severe consequences, including legal action, reputational damage, and financial penalties.

Thorough research and continuous monitoring of evolving industry standards and regulations are critical. Keeping up with these changes ensures that your practices remain compliant and minimizes the risk of non-compliance penalties.

Maintaining Traceability Throughout the Process

Maintaining comprehensive traceability throughout the entire production process is essential for effective quality management. Detailed records of materials, processes, and personnel involved in each stage provide a clear audit trail. This capability facilitates quick identification of potential issues and allows for swift corrective actions.

Maintaining accurate and detailed records of materials, processes, and personnel is not just about compliance; it's also about improving efficiency. Clear traceability allows for faster identification of problems and the ability to efficiently trace them back to their root causes, leading to quicker solutions and fewer disruptions.

Implementing Effective Communication Protocols

Effective communication protocols between all stakeholders, including suppliers, manufacturers, and customers, are vital for ensuring smooth operations and maintaining quality standards. Open communication channels facilitate the prompt exchange of information regarding issues, concerns, or potential deviations from established standards.

Building a Culture of Continuous Improvement

Cultivating a culture of continuous improvement is key to maintaining quality and compliance in the long term. Encouraging employees at all levels to identify and suggest improvements to processes is crucial for ongoing enhancement of quality control systems. Regular feedback mechanisms and employee recognition programs can foster a proactive environment for improvement.

Implementing a robust system for collecting and analyzing feedback from employees, customers, and suppliers is paramount to identifying areas for improvement. This feedback provides valuable insights into the effectiveness of existing procedures, highlighting areas where adjustments can lead to enhanced quality.