How to Select the Right Materials for Renovation Projects

Considering Aesthetics and Style: Matching Materials to Your Vision

Understanding Your Vision

Before selecting materials, pause to clarify your design vision. Do you prefer sleek modernity or classic elegance? The emotional tone of your space matters deeply—cozy warmth demands different materials than crisp minimalism. Pro tip: Collect fabric swatches, paint chips, and magazine clippings to create a physical mood board that captures your ideal aesthetic.

Notice how light interacts with different surfaces throughout the day. Morning sun reveals textures differently than evening lamplight—this awareness will guide smarter material choices.

Considering Functionality and Durability

Aesthetics matter, but real-life performance matters more. That gorgeous marble countertop might stain in a busy kitchen, while engineered quartz offers similar beauty with better resilience. Always test materials in their intended environment—spill coffee on samples, scratch them with keys, expose them to sunlight.

High-traffic areas need warrior materials that can take daily punishment while maintaining their good looks. Don't just read specs—visit showrooms and ask to see floor samples that have endured real-world use.

Exploring Natural Materials

Nothing beats the organic charm of materials formed by nature. Each wood plank tells a story through its grain, while natural stone offers geological artistry. But remember: these materials live and breathe—they'll expand, contract, and develop patinas over time. That's not damage, it's character.

For wood selection, consider end-grain patterns for cutting boards or rift-sawn oak for consistent vertical grain. With stone, sealed matte finishes hide fingerprints better than polished surfaces in busy homes.

Investigating Synthetic Materials

Today's synthetics are revolutionizing design. Porcelain slabs now mimic book-matched marble without the maintenance, while luxury vinyl planks fool even flooring experts. The best synthetics combine realistic textures with indestructible performance—look for options with embossed-in-register patterns that align with the visual design.

When evaluating synthetics, check the wear layer thickness—the thicker this protective coating, the longer the product will last. For high-traffic areas, aim for at least 20 mil.

Matching Materials to Room Function

Smart material choices begin with honest assessments of room usage. That Instagram-perfect white bouclé sofa? Maybe reconsider if you have kids or pets. Create a hierarchy of durability—assign tougher materials to high-impact zones while reserving delicate options for low-traffic sanctuaries.

In wet areas, prioritize materials with low water absorption rates (<1%). For flooring, check hardness ratings—the Janka scale for wood or PEI ratings for tile indicate scratch resistance.

Budgeting and Planning

Material costs can spiral quickly without careful planning. Implement the 70/20/10 rule: Allocate 70% of budget to primary surfaces, 20% to secondary elements, and 10% for unexpected upgrades. Always order 10-15% extra material to account for cuts, breaks, and future repairs.

Time your purchases strategically—many retailers offer seasonal discounts on flooring in January or outdoor materials in late summer. Consider remnant sales for smaller projects.

Considering Maintenance and Longevity

The true cost of any material includes its lifetime care. That stunning black granite countertop? Prepare for daily polishing to maintain its luster. Create a maintenance calendar for each material—seal natural stone annually, refinish hardwood every 7-10 years, deep clean upholstery biannually.

For busy households, look for materials with built-in protection like stain-resistant carpet fibers or scratch-guard laminate coatings. These technologies have improved dramatically in recent years.

Community education initiatives weave through neighborhoods like vital networks, creating learning opportunities in unexpected places. The pop-up story nook near the bakery or the math games painted on playground pavement represent education's evolving landscape. Smart designers sync programming with community rhythms—holding literacy sessions during morning market hours or STEM activities when parents collect children from school.

Exploring Different Material Options: From Tiles to Wood

Exploring the Advantages of Metal

Metal's unique properties make it indispensable across industries. Beyond its obvious strength, modern metallurgy creates alloys with surprising characteristics—some titanium alloys are stronger than steel yet half the weight. For architectural applications, consider weathering steel that forms a protective rust patina, eliminating the need for paint.

When specifying metals, thickness matters more than you might think. Sixteen-gauge steel has twice the thickness of eighteen-gauge—critical for durability in high-stress applications.

Delving into the Properties of Polymers

The polymer revolution continues to surprise. Self-healing plastics containing microcapsules of monomer can repair scratches when heated. Phase-change polymers now regulate temperatures in everything from athletic wear to building insulation. For designers, the ability to injection-mold complex shapes opens unprecedented creative possibilities.

When selecting polymers, check their UV stability ratings—many degrade in sunlight unless properly stabilized. Also consider recycling codes to ensure end-of-life sustainability.

Understanding the Versatility of Ceramics

Modern ceramics go far beyond bathroom tiles. Zirconia ceramics now replace metal in joint replacements due to their biocompatibility. Transparent aluminum oxynitride serves as bulletproof windows, while piezoelectric ceramics convert pressure into electricity. In home applications, nano-coatings make ceramic surfaces stain-proof and bacteria-resistant.

For flooring, ceramic's thermal mass helps regulate indoor temperatures—perfect for radiant heat systems. Just ensure proper subfloor preparation to prevent cracking.

Analyzing the Properties of Composites

The magic of composites lies in their synergistic combinations. Carbon fiber reinforced polymers achieve strength-to-weight ratios impossible with metals alone. New bio-composites combine natural fibers with plant-based resins, offering sustainable alternatives for furniture and automotive interiors.

When working with composites, remember they often have directional strength—their performance varies depending on load orientation. Always consult engineering specifications.

Investigating Advanced Materials

Materials science breakthroughs are redefining possibilities. Aerogels—the world's lightest solids—provide incredible insulation with minimal thickness. Metamaterials with engineered nanostructures can bend light or sound in extraordinary ways, enabling everything from super-lenses to acoustic cloaking.

Many advanced materials require specialized installation techniques. Always verify compatibility with standard construction practices before specification.

Exploring Sustainable Material Choices

True sustainability considers full lifecycle impacts. Rapidly renewable bamboo reaches maturity in 3-5 years versus decades for hardwoods. Mycelium-based materials grown from mushroom roots offer compostable alternatives to plastic foams. Even concrete gets greener with CO2-absorbing formulations.

When evaluating green claims, look for third-party certifications like Cradle to Cradle or Environmental Product Declarations (EPDs).

Evaluating the Cost-Effectiveness of Different Materials

Smart material economics consider total cost of ownership. That inexpensive vinyl flooring might need replacement in 7 years, while quality hardwood could last decades. Factor in installation costs—some materials require specialized labor that doubles project expenses. Also consider resale value—certain upgrades like natural stone counters consistently boost home values.

For large projects, request material samples in bulk quantities—colors and textures sometimes vary between small swatches and full-scale production.

Making the Final Selection: A Step-by-Step Approach

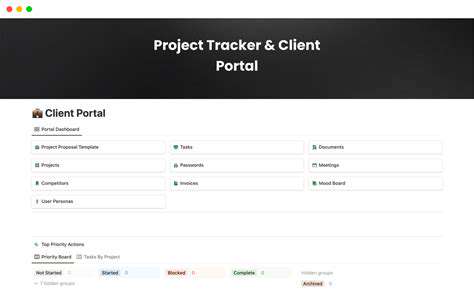

Evaluating Criteria

Final decisions demand rigorous analysis. Create a weighted scoring system that prioritizes your non-negotiables—maybe durability scores 40% while aesthetics gets 30%. Pro tip: Build physical comparison boards showing all options side-by-side under identical lighting conditions. Differences become obvious when viewed simultaneously.

For critical applications, order full-size samples rather than relying on small swatches. How a material feels at human scale often surprises.

Considering Alternatives

The best solutions sometimes come from left field. That commercial-grade carpet tile designed for airports? It might be perfect for your basement rec room. Cross-pollinate ideas between industries—medical-grade antimicrobial surfaces could revolutionize kitchen design. Always ask suppliers about new or unusual applications for their products.

When alternatives seem equally good, sleep on it. Fresh eyes often spot subtle advantages after a break.

Understanding Implications

Every choice creates ripple effects. That beautiful but delicate wallcovering might require special cleaning methods. Map out the domino consequences—selecting heavier materials may require structural reinforcements, adding cost and complexity. Consider how materials will age—will that trendy finish look dated in five years?

For renovations, verify existing conditions might affect new materials—moisture levels, substrate stability, or compatibility with adjacent surfaces.

Addressing Potential Risks

Mitigate risks with smart planning. Order extra material from the same production batch to ensure color consistency for future repairs. For critical applications, install test sections to evaluate real-world performance before full commitment. Document all specifications meticulously—product names, lot numbers, installation details—for future reference.

Build contingency budgets (10-20% extra) for unexpected challenges. Even professionals encounter surprises during installation.