How to Optimize Material Selection in Full Package Renovation Projects

Defining Your Scope

Before diving into renovations, homeowners must establish clear project boundaries. This goes beyond simple wish lists to address practical constraints and potential obstacles. Proper scope definition prevents budget overruns and timeline delays, eliminating unpleasant financial surprises later. Meticulous preparation - including precise measurements and honest evaluation of project complexity - forms the foundation for success.

Identify specific renovation targets: Is this a complete kitchen transformation, bathroom upgrade, or whole-house flooring replacement? Detailed initial planning creates clarity. A comprehensive scope document helps visualize outcomes and aligns all parties involved.

Budgeting and Financing

All renovations require financial planning. Creating an accurate budget protects against monetary stress during and after construction. Investigate material costs, labor rates, and permit requirements to develop thorough estimates. Remember to include contingency funds for unexpected expenses.

Evaluate financing alternatives carefully. Home equity lines, personal loans, and renovation-specific financing can alleviate cash flow pressure. Compare lender terms, interest rates, and fees to identify optimal solutions. Long-term repayment implications should weigh heavily in financing decisions.

Material Selection and Design Inspiration

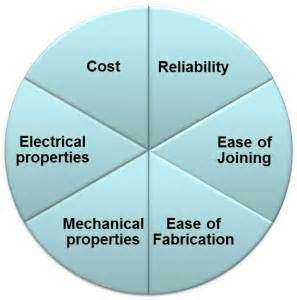

Material choices significantly impact both aesthetics and durability. Evaluate factors like resilience, maintenance needs, and personal taste. Research flooring options, countertop materials, and cabinetry varieties to find ideal matches. Thoughtful selection ensures renovations remain attractive and functional for years.

Gather ideas from diverse sources. Browse design publications, online resources, and social platforms to create vision boards. Visual representations help contractors and designers understand your preferences clearly. This collaborative approach yields spaces that authentically reflect your style.

Timeline and Contractor Selection

Renovations often operate on tight schedules, particularly for extensive projects. Develop practical timelines accounting for permitting, material delivery, and installation phases. Clear scheduling maintains progress and manages expectations realistically. Build buffer time for potential delays like weather disruptions or supply chain issues.

Choosing qualified contractors proves equally vital. Vet candidates thoroughly through reference checks and portfolio reviews. Evaluating contractor track records provides confidence and improves project outcomes. Skilled professionals deliver work meeting the highest quality standards.

Performance and Durability: Ensuring a Long-Lasting Project

Material Selection: The Foundation of Performance

Material decisions fundamentally affect project longevity. Material behavior varies under environmental stress and usage conditions. Consider intended use, load requirements, and exposure factors carefully. Corrosion-prone materials fail outdoors, while low-strength options buckle under heavy loads.

Understand material characteristics like tensile strength, flexibility, and environmental resistance. Review technical specifications, conduct preliminary testing, and consult specialists when needed. Informed choices reduce failure risks and extend service life.

Design for Strength and Stability

Structural integrity begins with sound design principles. Accurate load calculations form the cornerstone. Engineers must assess all potential forces - static, dynamic, and environmental - that structures might encounter. Robust designs incorporate safety margins to prevent catastrophic failures.

Manufacturing Processes and Quality Control

Production methods critically influence final product quality. Optimized manufacturing ensures material consistency and defect reduction. Advanced techniques like precision machining or additive manufacturing can enhance durability through superior accuracy. Stringent quality protocols at each production stage maintain standards and catch flaws early.

Comprehensive inspection regimes, including non-destructive testing, verify compliance with quality requirements. These procedures identify weaknesses that could compromise long-term performance.

Environmental Considerations: Protecting Against Degradation

Temperature variations, moisture exposure, and chemical contact all affect material performance. Understanding these interactions enables effective protective measures. Specialized coatings and treatments can dramatically extend product lifespans.

Outdoor applications demand weather-resistant materials. Proper sealing and waterproofing prevent moisture infiltration and subsequent deterioration.

Maintenance and Repair Strategies

Proactive maintenance extends project viability. Regular inspections, cleaning, and lubrication identify issues before they escalate. Detailed maintenance schedules with specific procedures keep projects functioning optimally throughout their lifecycle.

Future-Proofing Designs: Adapting to Changing Needs

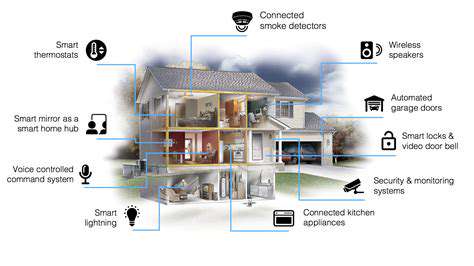

Anticipating evolution prevents premature obsolescence. Modular designs facilitate upgrades as requirements change or technologies advance. Incorporating expansion capacity ensures projects remain relevant longer.

Cost-Effective Strategies for Durability

Balancing quality and affordability requires creativity. Alternative materials, optimized designs minimizing waste, and efficient production methods can reduce costs without sacrificing durability. Lifecycle cost analysis should include maintenance and repair expenses alongside initial investments.

Cable-free charging represents the next evolution in electric vehicle power solutions.

Sustainability and Environmental Impact: Making Eco-Conscious Choices

Sustainable Practices in Industrial Processes

Eco-conscious operations minimize environmental harm while ensuring business continuity. Sustainability initiatives span energy reduction, waste minimization, renewable adoption, and resource optimization. These practices generate cost efficiencies while benefiting ecosystems, fostering responsible industrial development.

Sustainable material sourcing represents a critical component. Selecting environmentally friendly raw materials reduces overall production impacts.

Environmental Regulations and Compliance

Regulatory adherence constitutes both legal requirement and ethical imperative. Compliance demonstrates environmental responsibility while avoiding penalties. This demands thorough understanding of applicable standards and active implementation of compliance measures.

Meeting regulations often requires investments in emission controls, waste management systems, and pollution prevention technologies. These commitments ultimately benefit both corporate interests and planetary health.

Resource Efficiency and Conservation

Optimal resource use reduces industrial environmental footprints. Efficiency strategies target material waste reduction, energy conservation, and recycled content maximization. Water stewardship forms another crucial conservation aspect.

Resource efficiency delivers long-term cost benefits through reduced material needs and lower environmental remediation expenses.

Waste Management and Recycling

Comprehensive waste systems underpin sustainable operations. Effective waste reduction paired with robust recycling minimizes industrial environmental impacts. Proper waste segregation, processing, and disposal limit landfill use while recovering valuable materials.

Strategic waste management cuts disposal costs and enables material reuse, creating circular systems that enhance sustainability and reduce pollution.

Environmental Impact Assessment and Monitoring

Thorough EIAs identify potential ecological consequences before project commencement. These evaluations analyze air, water, soil, and biodiversity effects, informing mitigation planning. Continuous environmental tracking verifies mitigation effectiveness and ensures ongoing compliance.

Proactive monitoring enables timely process adjustments, minimizing environmental damage while maximizing protection efforts.